An oxygen sensor controls a vehicle’s pollution by eliminating the emission norms from the engine. The engine is fully operated by fossil fuel which has a high pollution rate. It senses the oxygen present in the exhaust gas and helps to eliminate the oxygen from the exhaust.

In this article, I will discuss how the oxygen sensor controls pollution in a vehicle.

Oxygen Sensor

An oxygen sensor, also known as an O2 sensor, is a crucial component in a vehicle’s exhaust system. Its primary function is to measure the amount of oxygen in the exhaust gases and provide feedback to the engine control module (ECM) or powertrain control module (PCM).

The information gathered by the sensor helps the engine management system optimize the air-fuel mixture for combustion. This, in turn, enhances fuel efficiency, reduces emissions, and ensures proper engine performance.

There are typically one or more oxygen sensors in a vehicle, located along the exhaust system. Modern vehicles often have both upstream (pre-catalytic converter) and downstream (post-catalytic converter) oxygen sensors. The upstream sensors monitor the air-fuel mixture before it enters the catalytic converter, while the downstream sensors check the efficiency of the catalytic converter in reducing emissions.

If this sensor fails or becomes faulty, it can lead to poor fuel efficiency, increased emissions, and potential engine performance issues.

Read More- 20 Automotive Garage Tools and Equipment for Technician

How Oxygen Sensor Controls Pollution

This sensor plays a crucial role in controlling pollution by helping regulate the air-fuel mixture in a vehicle’s engine. It operates within the context of the engine control system to optimize combustion, thereby reducing harmful emissions.

The primary function of this sensor is to measure the concentration of oxygen in the exhaust gases. It detects whether the air-fuel mixture is rich (too much fuel) or lean (too little fuel) during combustion. based on this information, the sensor sends real-time data to the ECM or PCM. This information is crucial for the engine management system to make immediate adjustments to the fuel injection process.

The engine control system uses the data from this sensor to adjust the air-fuel mixture. If the sensor indicates a rich mixture, meaning too much fuel is present, the system will reduce the fuel injection to achieve a more balanced mixture. Conversely, if the mixture is lean, the system will increase the fuel injection.

Downstream oxygen sensors, located after the catalytic converter, play a role in monitoring the converter’s efficiency. They ensure that the catalytic converter is effectively reducing harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons.

The oxygen sensor helps the engine burn fuel more efficiently by continuously adjusting the air-fuel mixture. This optimization minimizes the production of harmful emissions during combustion, contributing to lower levels of pollutants released into the environment.

Read More- What is a Constant Volume or Explosion-Type Gas Turbine?

Oxygen Sensor Circuit

The oxygen sensor circuit is an integral part of a vehicle’s engine control system, and it involves the interaction between the O2 and engine control module (ECM) or powertrain control module (PCM).

Modern vehicles typically have one or more oxygen sensors located along the exhaust system. The most common locations are upstream (before the catalytic converter) and downstream (after the catalytic converter).

The oxygen sensor produces a voltage signal that varies between 0.1 and 0.9 volts. A low voltage (close to 0.1V) indicates a lean air-fuel mixture, while a high voltage (close to 0.9V) indicates a rich mixture. The voltage signal from the oxygen sensor is sent to the ECM or PCM, which is the central computer controlling the engine. The ECM/PCM interprets this signal to determine the air-fuel mixture’s richness or leanness.

Based on the sensor’s feedback, the ECM/PCM adjusts the duration of fuel injection pulses to achieve the optimal air-fuel ratio for combustion. This is crucial for engine efficiency and emissions control. The system operates in a closed-loop fashion, meaning it continuously monitors and adjusts the air-fuel mixture in real-time. This dynamic feedback loop allows for precise control and optimization.

Some O2 have a built-in heating element to bring the sensor to an optimal operating temperature quickly. This is especially important during cold starts when the exhaust gases may not be warm enough to generate an accurate signal.

Read More- Environmental Management System for Automobiles.

Types of Oxygen Sensors

There are several types of oxygen sensors, each with its own design and operating principles. The two most common types are zirconia sensors and titania sensors. Here’s an overview of these two types:

- Zirconia Oxygen Sensor

- Titania Oxygen Sensor

1. Zirconia Oxygen Sensor

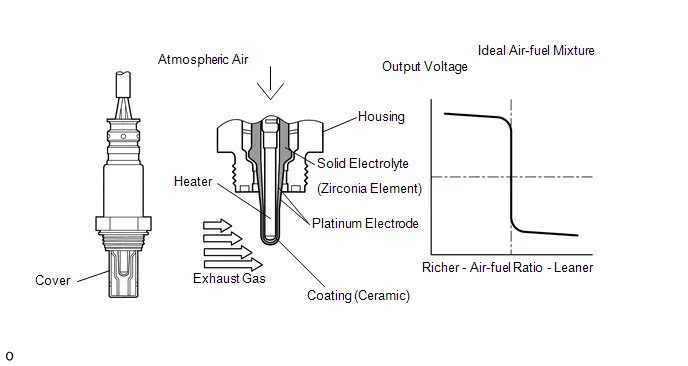

Zirconia sensors operate on the principle of the oxygen ion concentration difference between the exhaust gas and ambient air. The sensor consists of a ceramic element made of zirconium dioxide. At high temperatures (usually above 300°C or 572°F), zirconia becomes conductive to oxygen ions. The sensor measures the voltage generated by the difference in oxygen concentration between the exhaust gas and the outside air.

Zirconia sensors are commonly used in both upstream (pre-catalytic converter) and downstream (post-catalytic converter) positions in the exhaust system.

2. Titania Oxygen Sensor

Titania sensors operate based on the conductivity of titanium dioxide (titania). Similar to zirconia sensors, titania sensors measure the change in conductivity as a result of the difference in oxygen concentration. It operates at lower temperatures compared to zirconia sensors, typically around 200°C (392°F). They are often used in older vehicle models.

Titania sensors are less common in modern vehicles, as zirconia sensors have become the standard due to their faster response time and higher accuracy.

Read More- How Does a Brake Light Switch Work?

Advantages of Oxygen Sensor

The advantages of oxygen sensors are-

- One of the primary advantages of these sensors is their role in reducing harmful emissions from vehicles.

- It improves fuel efficiency by ensuring that the engine operates at the optimal air-fuel ratio.

- With the help of oxygen sensors, vehicles can more effectively meet stringent emission standards set by environmental regulations.

- It plays a crucial role in maintaining optimal engine performance.

- It contributes to the efficiency of catalytic converters.

- It operates in a closed-loop feedback system, providing real-time data to the engine control module (ECM) or powertrain control module (PCM).

Conclusion

In summary, the oxygen sensor circuit is a vital component of a vehicle’s engine control system, playing a key role in maintaining an optimal air-fuel mixture for combustion and ensuring compliance with emission standards.

Frequently Asked Question(FAQ’S)

How does the oxygen sensor work?

Oxygen sensors work by generating a voltage signal based on the difference in oxygen levels between the exhaust gas and ambient air. This signal is used by the engine control module to adjust the air-fuel mixture.

Where is the oxygen sensor located in a car?

Oxygen sensors are typically located along the exhaust system. There are usually one or more upstream sensors (before the catalytic converter) and downstream sensors (after the catalytic converter).

Can a faulty oxygen sensor affect fuel efficiency?

Yes, a faulty oxygen sensor can significantly impact fuel efficiency. If the sensor is not providing accurate feedback to the engine control module, it can result in an improper air-fuel mixture, leading to reduced fuel efficiency.

Do comment here