What are Rocker Arms in Engine is discussed in this article. The rocker arms are the component that opens and closes the engine valves. The main and only purpose of the rocker arms is to open and close the engine gat, the valves. In this article, I will discuss the benefits and the working of these Rocker Arms in the engine.

[lwptoc]

What are Rocker Arms?

The rocker arm is a “U” shaped component that is pivoted in the middle section and helps open and close the engine valves. The engine crankshaft operates this arm. The rockers arm is part of the engine valve train where the operation of the engine valves depends upon the movement of these arms.

These arms are made of high aluminum or alloy steel, as they must withstand the thrust and pressure due to the engine movement and the valve spring tensions. The engine valves have the springs to make them return to their place. A rocker arm needs to be hard and powerful to push these valves on time.

These arms are special because all the work depends on the engine power. So, there is somehow a little amount of power disturbed due to operating these components. That’s why nowadays these rockers arm is discontinued in the engine.

If someone asked what are rocker arms– then the answer would be that rocker arms are such components in the engine that take the engine power to operate the opening and closing of the engine valves. It’s like taking its power to generate its power.

Read More- Spring Loaded Valve | Meaning of Spring Loaded Valve.

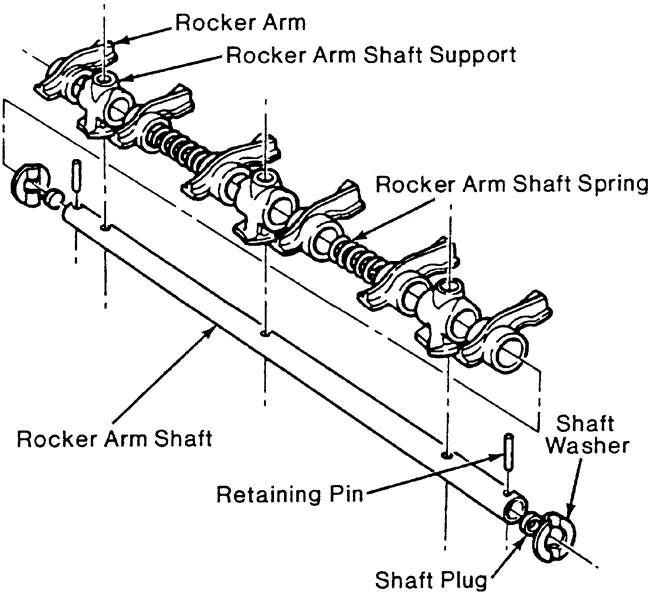

Parts of Rocker Arm

The proper functioning of the rocker arm’s parts is essential for maintaining engine performance and efficiency. So, the parts are-

1. Rocker Arm Body

The main structural component of the rocker arm, often shaped like an “L” or “U,” connects to the engine’s valve and receives motion from the camshaft. This body helps to open and close the engine valves.

2. Rocker Arm Shaft

The shaft on which the rocker arm pivots. It is mounted within the engine’s cylinder head and allows the rocker arm to move as the camshaft lobes act upon it. These shaft needs to be lubricated well to function and operate. The rocker arm shaft is responsible for better operation of the rockers.

3. Rocker Arm Adjuster

Some rocker arms have an adjuster mechanism, such as a set screw or nut, to enable precise control of valve clearance. This is important for maintaining proper valve timing and performance. When the engine temperature rises the tip of the rocker arm increases, then this component is used to control the gaps.

4. Pushrod

These pushrods are connected to the engine camshaft in the engine block. These pushrods push the engine rocker arms to operate to open and close the valves. The push rods of the engine are responsible for operating the rocker arm at the perfect time.

5. Tappet

The tappet is the front part of the rocker arm. This tappet makes the connection to the valve tip that pushes the body of the valve. The gap between the tappet and the valve tip is called tappet clearance. This tappet gap needs to operate carefully to function the engine operations.

6. Valves

Engine valves are the last leading component of these rocker arms. These valves are important to make the combustion in the engine in a sequence. So, opening and closing of these valves at the correct time is more important and this s happens with the help of the rocker arm.

Read More- In-line Fuel Injection Pump (Diesel Engine).

The Function of Rocker Arms

However, this is important to know how these rocker arms work in an engine. The rocker arm takes the engine power to operate and helps the engine valves to open and close at the right time. Though this component is very small in size, it has big responsibilities.

The primary function of rocker arms in an internal combustion engine is to transfer the motion from the engine’s camshaft to the engine valves. The camshaft has lobes that push against the rocker arms, causing them to pivot on their shafts. This motion is then transmitted to the valves, either directly or through pushrods and lifters, resulting in the opening and closing of the valves.

Rocker arms convert the rotational motion of the camshaft into linear motion, which is used to actuate the opening and closing of the engine valves. This is crucial for controlling the intake and exhaust processes in the combustion cycle.

In some engine designs, rocker arms incorporate an adjuster mechanism that allows for the fine-tuning of valve clearance. Proper valve clearance is important for maintaining engine efficiency and preventing issues like valve lash.

Types of Rocker Arms

There are 4 types of rocker arms used in an engine. These types are-

- Stamped steel type.

- Roller-tipped type.

- Full roller type.

- Shaft rocker type.

1. Stamped Steel Type

These are typically simple, cost-effective rocker arms produced by stamping a flat piece of metal into the desired shape. Stamped rocker arms are commonly used in less performance-oriented engines and are often found in applications where cost is a significant factor.

2. Roller-Tipped Type

Roller-tipped rocker arms have a roller bearing on the end that makes contact with the valve stem. This design reduces friction and wear, making roller-tipped rocker arms suitable for high-performance engines where smoother valve action and increased durability are desired.

Read More- What is the Uses of Catalytic Converter in a Vehicle?

3. Full-Roller Type

In this type, both the rocker arm body and the roller tip are equipped with roller bearings. Full roller rocker arms further reduce friction, provide enhanced durability, and are commonly used in high-performance and racing engines where precise valve control is crucial.

4. Shaft Rocker Type

In some engine designs, rocker arms are mounted on a shaft that spans the cylinder head. This configuration provides stability and reduces deflection, making it suitable for high-performance and racing applications.

Materials of Rocker Arm

The choice of material depends on the specific application, performance requirements, and cost considerations. A rocker arm needs to be hard and cost-efficient as well as it needs to be light in weight. So, the engine speed can match the opening of the valves.

Aluminum alloy rocker arms are popular in many modern engines due to their lightweight nature. The reduced mass helps in minimizing reciprocating weight and inertia, contributing to higher engine RPM potential. These rocker arms are commonly used in both performance and standard applications.

There are also other materials used like- Forged steel, Cast iron, Stamped steel, Stainless steel, Titanium, etc. In heavy trucks or heavy vehicles forged steel type of Cast iron type components are used.

Symptoms of Rocker Arm

The rocker arm is important to operate the engine in its best condition. No one can drive a vehicle with a braking rocker arm. So, one needs to understand the symptoms of the rocker arm. So these symptoms are-

1. Tic-Tic Sound

If someone notices tic-tic sounds coming from the engine side then the rocker arm is disputed. It happens when the gap between the rocker arm tip and the valve tip is mismatched.

This noise may be more pronounced during acceleration and can indicate problems with the rocker arms not moving smoothly or making proper contact with the camshaft.

Read More- What is the Function and Working of Hand Brake System?

2. Engine Misfire

If the rocker arms are not functioning correctly, the opening and closing of the engine valves may be disrupted. This can lead to misfires, causing the engine to run unevenly or experience a rough idle.

An engine misfire can lead to engine damage. This engine misfire can be solved by filling the gap between the tappet and the valve tip.

3. Check Engine Light

Issues with the rocker arms may trigger the engine control unit (ECU) to illuminate the check engine light on the dashboard. The ECU detects irregularities in the engine’s performance and signals the need for diagnostics.

4. Oil Leaks

Rocker arms are often lubricated with engine oil. If there are leaks in the valvetrain, it can result in inadequate lubrication of the rocker arms, leading to increased friction and wear.

Advantages of Rocker Arm

The advantages of rocker arm are

- Rocker arms are essential for converting the rotational motion of the camshaft into linear motion to actuate the opening and closing of engine valves.

- Rocker arms provide a mechanical advantage by amplifying the motion generated by the camshaft.

- Many rocker arm designs incorporate adjustability, allowing for fine-tuning of valve clearance.

- Properly designed rocker arms help distribute the forces exerted by the camshaft on the valve, minimizing wear on both components

- Advanced materials like aluminum alloy and cast irons are used to make this product.

- In high-performance and racing applications, rocker arms can be designed with adjustable ratios, allowing tuners to customize valve lift.

- Rocker arms are adaptable to various engine configurations, including overhead valve (OHV), overhead camshaft (OHC), and dual overhead camshaft (DOHC) setups.

Read More- What is the Function of Regenerative Braking?

Disadvantages of Rocker Arms

The disadvantages of Rocker arms are-

- These arms, especially those without roller bearings, can experience friction and wear over time.

- While adjustability is considered an advantage, it can also be a disadvantage if not properly maintained.

- In some applications, the weight of rocker arms, especially those made from certain materials like steel, can contribute to increased reciprocating mass.

- Depending on the material and design, rocker arms may be susceptible to fatigue over time, particularly in high-stress or high-performance applications.

Conclusion

In summary, rocker arms are integral components of an engine’s valvetrain system, responsible for converting the camshaft’s rotational motion into the precise linear motion needed to control valve operation. By regulating valve timing, lift, and clearance, rocker arms contribute to the overall performance, efficiency, and reliability of an internal combustion engine.

Frequently Asked Questions(FAQ’S)

How does a rocker arm work in the valvetrain system?

The rocker arm pivots on a shaft, responding to the camshaft’s lobes. As the camshaft rotates, it pushes against the rocker arm, causing it to move and actuate the valves.

Why is adjustability important in rocker arms?

Adjustability allows for fine-tuning of valve clearance, ensuring optimal valve operation. This is particularly crucial in maintaining engine performance and preventing issues like valve lash.

What is the purpose of shaft-mounted rocker arms?

Shaft-mounted rocker arms provide stability to the valvetrain, reducing deflection and contributing to precise valve timing. This design is often preferred in high-performance and racing applications.

Do comment here