Last Updated on 22 July 2024 by automobilehut.in

The mass air-flow sensor is one type of fuel-efficient sensor used in automobile vehicles to detect and control the airflow in a vehicle. This sensor is used to detect the amount of air coming into the intake manifold and sends this sense to the ECU. In this article, I will discuss the details of the mass air flow sensor working principle and the usage of this sensor.

Air Flow Sensor Working

There are a lot of sensors used in automobile vehicles to regulate the engine and the other equipment precisely. The Mass airflow sensor is one of them. This sensor helps to translate the quantity of air entering the car’s engine into a voltage signal to determine the engine’s load is the airflow sensor, also known as the mass airflow (MAF) sensor.

Air flow sensors are used in different systems and industries. This sensor is essential for preserving the best possible fuel economy and emissions in automobiles, and it assists the engine control unit in regulating fuel injection to guarantee effective combustion.

This MAF sensor in a vehicle is located in the Intake manifold. This Intake Manifold is a type of hollow tube from which the air enters. This sensor is used to sense the amount of air coming through it and it indicates the actuators to do their jobs.

If someone asks what is air flow sensor then the answer will be, that this is the sensor used in automobile vehicles to regulate the amount of air coming into the engine from the atmosphere and sends this sense to the ECU. Let’s read about the working principle.

Read More- Understand the Engine Firing Order and Its Importance.

Mass Air Flow Sensor Working Principle

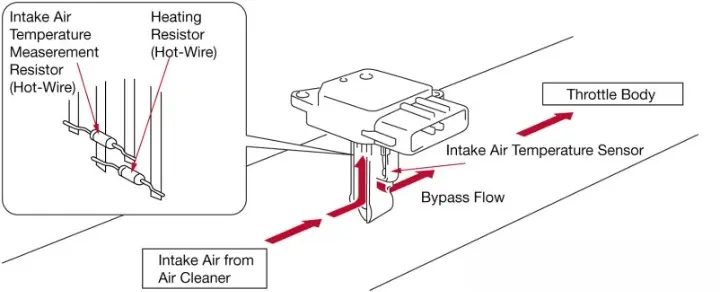

The MAF sensor is located in the intake manifold air filter and throttle body. Its primary function is to measure the amount of air entering the engine, providing crucial data to the engine control unit (ECU) for optimizing fuel injection and achieving efficient combustion. The working principle of an airflow sensor is based on various techniques, but the most common one is the hot wire or hot film method.

This method involves a thin wire or film positioned in the air intake path. This method involves a thin wire or film positioned in the air intake path. As air flows over the heated element, it cools down the wire or film. The amount of cooling is directly proportional to the mass or volume of air passing through. The sensor measures the electrical current required to maintain the constant temperature of the wire or film. A higher current indicates more cooling and, consequently, a greater airflow.

A higher current indicates more cooling and, consequently, a greater airflow. The ECU continuously strives to maintain the ideal air-to-fuel ratio for combustion efficiency and emission control. The relationship between airflow and the sensor’s output is typically linear. This linearity allows for accurate and predictable readings across a range of engine operating conditions.

Read More- CNG Conversion Kit Components | Details with the Installation Process.

The Mass Airflow Sensor Circuit

The core of the circuit is the airflow sensor element, often based on a hot wire or hot film technology. For a hot wire or hot film sensor, there is a heater element that warms the wire or film to a constant temperature. The circuit requires a power supply to provide the necessary voltage for the sensor element and other components.

The signal from the airflow sensor is often a variable resistance, voltage, or frequency signal. This signal processes and modifies the sensor signal to make it suitable for input to the engine control unit (ECU). Depending on the type of sensor output, there may be an amplification or conversion stage to ensure the signal is within the desired range.

The conditioned signal is then sent to the ECU through an output connector or wiring. Proper grounding is essential for the accurate functioning of the circuit. There is usually a ground connection to ensure a complete electrical circuit.

Read More- 20 Automotive Garage Tools and Equipment for Technician

Types of Mass Airflow Sensor

Depending upon the design and the diagram of the vehicle, an MAF sensor can have a lot of types. The different types of MAF sensors are-

1. Hot Wire MAF Sensor

This sensor utilizes a thin wire or film heated to a constant temperature. As air flows over the heated element, it cools down, and the amount of cooling is proportional to the mass or volume of air passing through. These types of sensors Provide accurate and responsive readings across a wide range of airflow conditions.

2. Vane Meter MAF Sensor

In this system, a movable vane (or flap) is placed in the airflow path. The vane is connected to a potentiometer or a variable resistor. As air flows, it pushes the vane, changing the resistance and producing a signal. This type of MAF sensor is less susceptible to contamination compared to hot wire sensors.

3. Karman Voretx MAF Sensor

This type of MAF sensor measures the frequency of vortices generated as air passes through a small aperture. The frequency is directly proportional to the air mass flow rate. This sensor has the major advantage that, this can provide accurate readings in a wide range of conditions.

4. Cooled Element MAF Sensor

Similar to the hot wire MAF sensor, but with an additional cooling mechanism. A portion of the airflow is directed to cool the heated element. This sensor can enhance the accuracy by compensating for variations in air temperature.

Read More- Read About the 4 Different Types of Wheels in the World.

How to Clean Mass Air Flow Sensor

Cleaning the mass air flow (MAF) sensor is a straightforward process, but it requires careful handling to avoid damaging the delicate components. First, ensure the engine is turned off and has cooled down before starting the cleaning process.

As per your vehicle’s service manual locate the MAF sensor. It is usually positioned in the air intake system, between the air filter and the throttle body. In some cases, you may need to remove the air intake duct to access the MAF sensor. Carefully unplug the electrical connector from the MAF sensor.

Visually inspect the sensor for any signs of dirt, debris, or contamination. Be gentle, as the sensor components are delicate. Hold the MAF sensor with the sensing elements facing down to prevent cleaner residue from getting on them. Liberally spray the MAF sensor cleaner onto the sensor elements. Ensure you cover all sides of the sensor.

Let the MAF sensor air dry completely. This typically takes about 10-15 minutes. Do not use compressed air or any foreign objects to speed up the drying process, as this may damage the sensor. Once the MAF sensor is dry, carefully reinstall it in the reverse order of removal.

Read More- Torque Converter Construction and Working Diagram.

Advantages of Mass Air Flow Sensor

The advantages of MAF sensors are-

- MAF sensors provide accurate and real-time measurements of the amount of air entering the engine.

- MAF sensors offer a quick and dynamic response to changes in airflow.

- By accurately measuring air intake, MAF sensors contribute to achieving the ideal air-fuel ratio.

- Accurate air measurement assists in maintaining proper combustion, which is essential for reducing harmful emissions.

- MAF sensors can work effectively with forced induction systems like turbochargers and superchargers.

- MAF sensors contribute valuable data to the onboard diagnostics system.

Disadvantages of Mass Air Flow Sensor

The disadvantages of mass air flow sensors are-

- MAF sensors can be sensitive to contamination from dirt, oil, or debris.

- Regular maintenance is often required to keep MAF sensors clean and functioning optimally.

- MAF sensors can be relatively expensive to replace if they fail or become damaged.

- In vehicles with oil-bathed air filters, excess oil from the filter may find its way to the MAF sensor and contribute to contamination.

- MAF sensors are electronic components that can be susceptible to electrical issues, such as wiring faults or connection problems.

Conclusion

In summary, the MAF sensors are special for engine combustion. This sensor is used in the vehicle to operate the air quantity in the engine. This sensor is located inside the intake manifold, in between the air filter and engine valves. Proper maintenance of this sensor can make the engine run better and in optimal condition.

Frequently Asked Questions(FAQ’S)

Why is the Mass Air Flow sensor important?

The MAF sensor provides real-time data on the air intake, allowing the Engine Control Unit (ECU) to adjust the fuel injection rate, ensuring the correct air-fuel mixture for optimal engine performance, fuel efficiency, and emission control.

What are the common types of MAF sensors?

Common types include Hot Wire MAF, Vane Meter MAF, Kármán Vortex MAF, Cooled Element MAF, and Capacitive MAF. Each type employs different technologies to measure airflow.

Are there alternative methods for measuring airflow in engines?

Yes, alternatives include speed density systems, which use manifold pressure and air temperature to estimate airflow, and alpha-N systems, which rely on throttle position and engine speed.