A Dry Sump Lubrication System is the type of pressure lubrication system used in aircraft or automobile sectors. This type of system is fit for high-speed vehicles or vehicles that need additional turns at high speeds. In this article, I will discuss how the Dry sump lubrication system works in the car.

Dry Sump Lubrication System

A dry sump lubrication system is also a type of pressure type lubrication system. This is used in the system to fulfill the requirements of the lubrication of the engine. The main focus of the system is to provide enough lubrication to the moving parts of the vehicle.

The pressure lubrication system has two types, one is the Wet sump lubrication system, which we see often in vehicles, and the other is the Dry sump lubrication system, which is used in high-speed vehicles. A dry sump system has the biggest advantage this system can provide better lubrication when the vehicle tilts or has high speeds.

Working of Dry Sump Lubrication System

A dry sump lubrication system is an engine lubrication method commonly used in high-performance vehicles, racing cars, and some aircraft engines. Unlike the traditional wet sump system where oil is stored in a single oil pan beneath the engine, a dry sump system separates the oil storage from the engine itself.

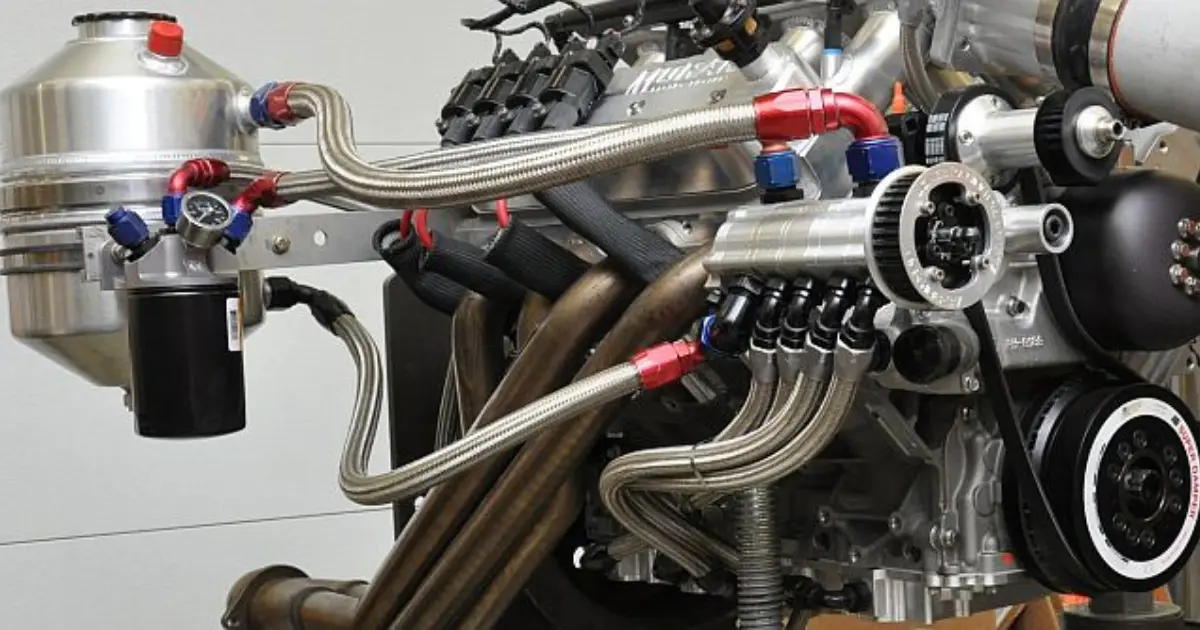

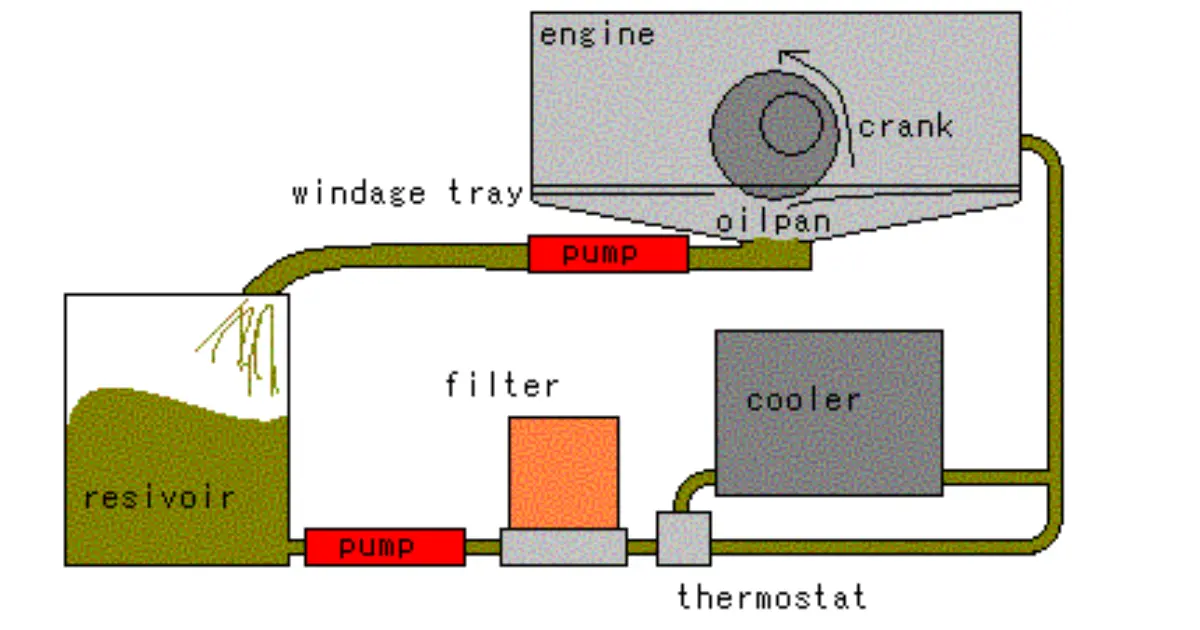

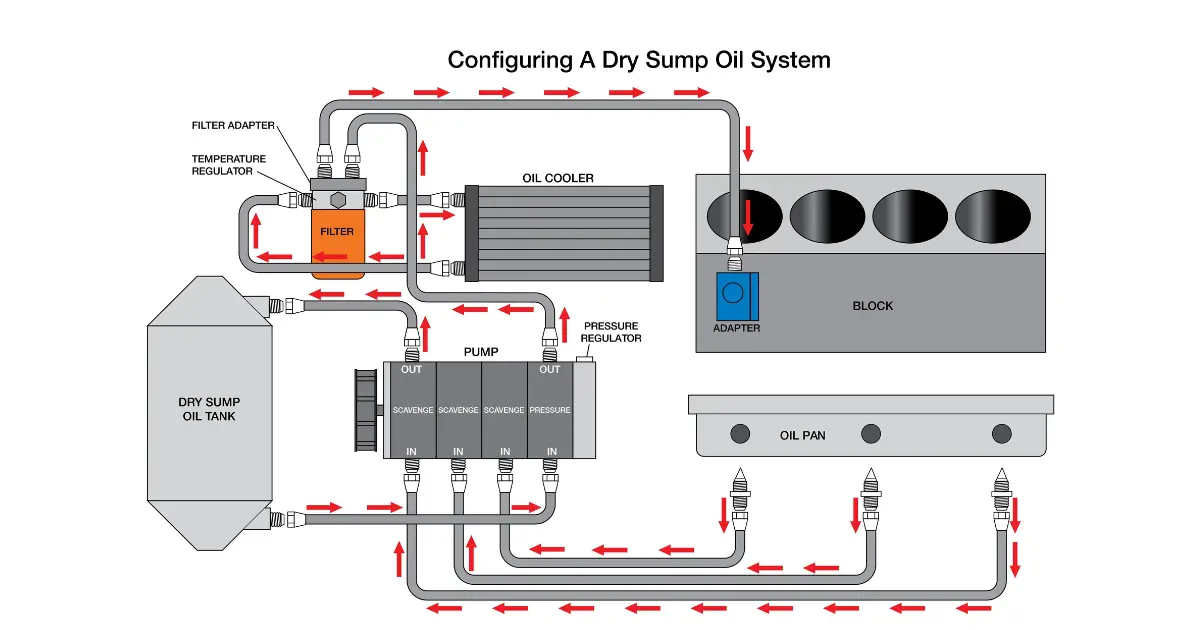

Instead of having an oil pan attached to the bottom of the engine, a separate oil tank is used to store the engine oil. This tank can hold a larger volume of oil compared to a traditional oil pan. This system includes a high-performance oil pump that is typically located externally and driven by a belt, chain, or gears. This pump draws oil from the storage tank and circulates it through the engine.

This oil pump generates the power itself and compresses the oil into it. The pump gives the oil to the different parts of the engine. After feeding the oil to the various points of the engine, the scavenging pump is used in the engine to suck the oil and sends it back to the dry sump pan. This scavenging process ensures that oil is continuously circulated and prevents it from pooling in the engine, which could lead to oil starvation during high-speed or high-G maneuvers.

A pressure regulator controls the oil pressure within the system. It ensures that the oil is delivered to critical engine components at the right pressure, preventing damage from either insufficient or excessive pressure.

This is how the whole system works in an engine. let’s see the function of the Dry sump lubrication system

Function of Dry Sump Lubrication System

A dry sump lubrication system is primarily designed to provide continuous and efficient lubrication to the engine’s moving parts, especially in high-performance or racing vehicles. The main function of the system is to provide effective lubrication to all engine parts.

By storing oil in a separate tank, the dry-sump system ensures a consistent supply of oil to the engine at all times, even during high-speed cornering, acceleration, or braking. So if the enigne tilts or brakes often this system will provide effective lubrication to the system.

Also, the dry-sump system it uses the oil cooler to cool down the engine oil. The dry sump lubrication system is used in performance vehicles and these vehicles need additional cooling except the engine cooling system. So, the lubricating oil is also used as a cooling media in the engine.

Components of Dry Sump Lubrication System

So the main components of this system are-

1. Oil Pan or Reservoir: In the dry sump lubrication system the oil is kept in another chamber. From this chamber, the oil is fed to the various engine parts. The main reason behind this system is this utilizes the perfect amount of oil in the chamber.

2. Oil Pump: The oil pump is responsible for drawing oil from the reservoir and circulating it through the engine. It maintains oil pressure and pressurizes the oil into it for better oil circulation. Also, this pump ensures keeping a continuous oil film between the two rubbing materials.

3. Oil Lines: These are the hoses or lines that connect the oil reservoir to the oil pump and distribute oil throughout the engine. They transport oil to various components, such as bearings, pistons, and valvetrain, ensuring proper lubrication.

4. Oil Cooler: In high-performance applications, an oil cooler may be incorporated into the system to help dissipate heat from the oil. This helps maintain optimal oil temperature and prevents oil breakdown under extreme operating conditions. Also, this system maintains the property of the oil.

5. Scavenge Pump(s): One or more scavenge pumps are used to collect oil from the engine’s crankcase and return it to the oil reservoir. These pumps remove excess oil to prevent windage losses and ensure efficient lubrication.

6. Oil Filter: A filter is typically installed in the oil circulation system to remove debris and contaminants from the oil, ensuring that only clean oil reaches the engine’s moving parts. These oil filters are fitted inside the pump for better rectification of the oil. Also, the big strainer-type filter is used to filter the bigger particles of the engine oil.

Oil Tank Breather: A breather system allows for the release of air pressure and vapors from the oil tank, preventing pressure buildup that could lead to leaks or other issues.

Differences Between Dry Sump and Wet Sump Lubrication Systems

So the differences of this system are-

| Aspect | Dry Sump Lubrication System | Wet Sump Lubrication System |

|---|---|---|

| Oil Storage | Oil is stored in a separate external reservoir or tank. | Oil is stored in a pan located directly underneath the engine. |

| Oil Pumping | Uses one or more pumps to draw oil from the external reservoir. | The oil pump is typically located within the engine’s oil pan. |

| Oil Capacity | Typically has a larger oil capacity. | Typically has a smaller oil capacity. |

| Oil Control | Offers better control over oil pressure and flow rates. | May experience oil starvation during extreme driving conditions. |

| Installation Complexity | More complex installation due to additional components. | Simpler installation with fewer components. |

Conclusion

So the dry sump lubrication system is the effective and continuous lubrication system used in a vehicle. When the vehicle tilts or has effective braking, the whole system with the oil also moves to the sides and this provides the oil level the same as the flat surface. Overall, a dry sump lubrication system offers superior lubrication and performance benefits, particularly in high-performance or racing applications where engine reliability and efficiency are paramount.

Read More- What is the Function of Lubricating Oil?