Throughout, recent years, you’ve probably heard progressively more about flex-fuel vehicles, regardless of whether you completely comprehend what they were. Today, various known flex-fuel benefits exist. Be that as it may, prior to putting resources into this kind of vehicle, you ought to initially comprehend what you’re buying. Fuel is a wellspring of energy. The consumption of fuel produces energy. Ethanol and gas are two sorts of fuel generally utilized in vehicles. The principal distinction between Ethanol and Fuel is that Ethanol is made out of just ethyl liquor atoms through Gas is made out of a few kinds of natural particles.

Flex Fuel-

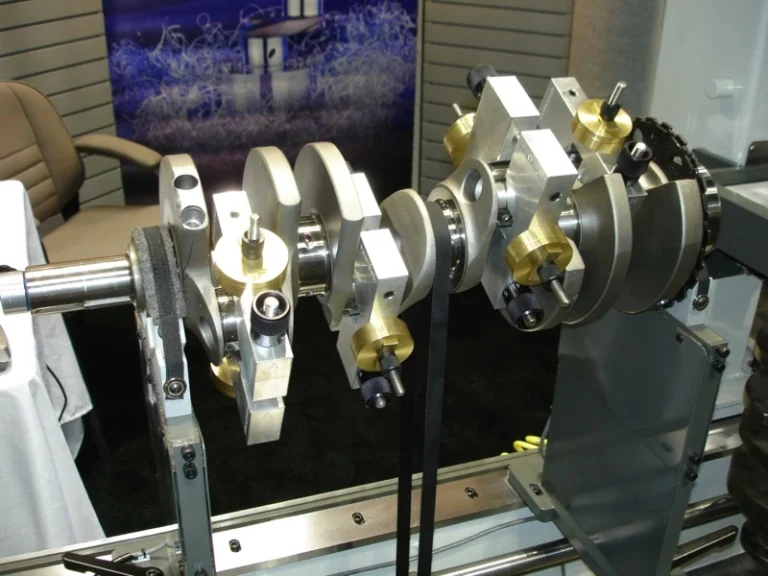

Flex fuel, or adaptable fuel, is an elective fuel made of a blend of gas and methanol or ethanol. Flex-fuel vehicles are those that have gas-powered motors intended to run on more than one kind of fuel. Other than a couple of changes to the motor and fuel framework. Flex-fuel crossover electric and flex-fuel module mixture are two sorts of half-and-half vehicles worked with a burning motor fit for burning gas.

In 2007 Passage created 20 show Departure Cross breed E85s for genuine testing in armadas in the U.SThis innovation isn’t new. It was first evolved in the mid-1990s and utilized in the efficiently manufactured 1994 Passage Taurus, as per Vehicle Books of scriptures. By 2017, there were around 21 million flex-fuel vehicles out and about.

Flex Fuel Benefits-

Let’s discuss the benefits of using flex fuel-

Environment-

Gasoline consequences for the climate. Ethanol consumes cleaner than gas, and that implies flex-fuel vehicles siphon less poisonous exhaust into the climate. Flex fuel likewise offers fewer ozone-depleting substances, making it more harmless to the ecosystem choice than conventional gas.

Performance-

While some could contend that utilizing an elective fuel source can adversely influence a vehicle’s exhibition, as a general rule it can make the contrary difference. Flex-fuel vehicles don’t encounter misfortune in execution while utilizing E85 fuel. Some even create expanded force and strength, as a matter of fact. Ethanol also produces that much power to move the vehicle and also provides great mileage. Many flex-fuel vehicles run on ethanol, which is economically delivered from fixings, for example, raw sweetener and corn. This makes ethanol a decent option in contrast to buying unfamiliar oil.

Technology-

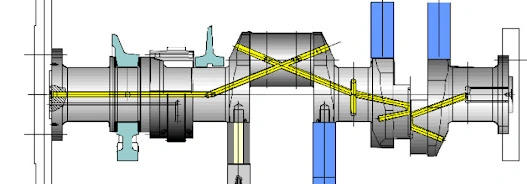

current flex-fuel vehicles are fabricated utilizing electronic sensors. As referenced, these mechanical advances permit your vehicle to change the manner in which it’s working, including recognizing the fuel mix and making any important changes. Current flex-fuel vehicles can contain 10 to 85 percent ethanol.

One of the best benefits of a flex-fuel vehicle is that it can consume anything extent of fuel combination in the burning chamber. The vehicle is furnished with electronic sensors that check the mix, and its microchips change the fuel infusion and timing.

Read more