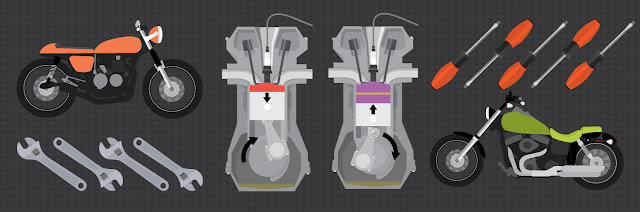

Motorcycle engine tuning–

Motorcycle engine tuning involves changing the air-fuel mixture, adjusting the ignition timing, or modifying the exhaust system. Proper tuning can improve the motorcycle’s power output, acceleration, and fuel efficiency. Both the changing improvements will be discussed later.

One of the primary components of motorcycle engine tuning is adjusting the fuel-air mixture. This is done by adjusting the carburetor or fuel injection system to achieve the optimal air-to-fuel ratio. The ideal ratio depends on the engine and the operating conditions, such as temperature and altitude. A lean mixture, where there is too much air and not enough fuel, can cause the engine to run hot and can lead to damage over time. On the other hand, a rich mixture, where there is too much fuel and not enough air, can cause the engine to run poorly and can reduce fuel efficiency.

Another important component of motorcycle engine tuning is adjusting the ignition timing. This involves adjusting the timing of the spark plug to ensure that the fuel-air mixture is ignited at the optimal time. This can significantly impact the engine’s power output and overall performance. Ignition timing is typically adjusted by rotating the distributor or by using a programmable ignition system.

Modifying the exhaust system is another way to improve the performance of a motorcycle engine. The exhaust system is responsible for expelling the exhaust gases from the engine, and a well-designed exhaust system can improve the engine’s power output and overall efficiency. This can be achieved by increasing the diameter of the exhaust pipe or by using a free-flowing muffler. However, it is important to note that modifying the exhaust system can also increase the noise level of the motorcycle, which may not be desirable in all situations.

In addition to these components, several other factors can affect motorcycle engine tuning. For example, the type of spark plug used can impact the engine’s performance, as can the quality of the fuel being used. The engine’s compression ratio can also have an impact on performance, with a higher compression ratio typically leading to increased power output. Finally, the weight of the motorcycle and its components can also impact its performance, with a lighter motorcycle typically performing better than a heavier one.

Motorcycle engine tuning process-

- Check the air filter first. A clogged air filter restricts airflow to the engine, reducing its performance. Remove the air filter and clean or replace it if necessary.

- Secondly, check the spark plugs. Spark plugs ignite the fuel-air mixture in the engine cylinders. Check the condition of the spark plugs and replace them if they are worn or fouled.

- Adjust the carburetor with the full process. The carburetor regulates the fuel-air mixture that enters the engine. Adjust the carburetor to ensure that the fuel-air mixture is optimal for the engine’s performance.

- Adjust the valve clearance with the filler gauge. The valve clearance determines how much the valves open and close. Adjust the valve clearance to ensure that the engine runs smoothly and efficiently.

- Ignition timing determines when the spark plug fires about the piston’s position in the cylinder. Adjust the ignition timing to ensure that the spark plug fires at the optimal time for the engine’s performance.

- Adjust the idle speed of the engine. The idle speed is the speed at which the engine runs when it is not under load. Adjust the idle speed to ensure that the engine runs smoothly and reliably.

It’s important to note that the exact steps required to tune a motorcycle engine will vary depending on the specific make and model of the motorcycle, as well as the type of engine it has.

Tuning BS6 motorcycle engine-

- Check the air filter: A clogged air filter restricts airflow to the engine, reducing its performance and increasing emissions. Remove the air filter and clean or replace it if necessary.

- Check the spark plugs: Spark plugs ignite the fuel-air mixture in the engine cylinders. Check the condition of the spark plugs and replace them if they are worn or fouled.

- Adjust the fuel injection system: BS6 engines are equipped with electronic fuel injection systems that precisely control the fuel-air mixture. Adjust the fuel injection system to ensure that the fuel-air mixture is optimal for the engine’s performance and emission compliance.

- Check the exhaust system: The exhaust system plays a crucial role in reducing emissions from the engine. Check the condition of the exhaust system and replace it if necessary. You may also consider installing a performance-oriented exhaust system for better performance.

- Check the ECU: The engine control unit (ECU) controls various engine functions, including fuel injection timing, ignition timing, and emission control. Ensure that the ECU is functioning correctly and update its software if necessary.

- Consult a qualified mechanic: Tuning a BS6 engine requires specialized knowledge and equipment. It’s always best to consult a qualified mechanic who has experience with BS6 engines for specific guidance on tuning your motorcycle’s engine.

It’s essential to note that tuning a BS6 engine must not compromise its emission compliance, which is crucial to protecting the environment and complying with regulations.

How does motorcycle engine tuning affect changing the air-fuel mixture?

- When the air-fuel mixture is too lean, meaning there is too much air and not enough fuel, the engine may run hot and can be damaged over time. This is because a lean mixture can cause the engine to run hotter than it was designed to, which can lead to overheating and potential damage. In addition, a lean mixture can cause the engine to run poorly and can reduce fuel efficiency.

- On the other hand, when the air-fuel mixture is too rich, meaning there is too much fuel and not enough air, the engine may run poorly and may also have reduced fuel efficiency. A rich mixture can cause the engine to run too cool, which can lead to incomplete combustion and increased emissions. It can also cause carbon buildup in the engine, which can lead to decreased performance over time.

By adjusting the air-fuel mixture to the optimal ratio, the engine can operate more efficiently and with improved performance. This can result in better acceleration, more power output, and improved fuel efficiency. It’s important to note that changing the air-fuel mixture can have significant impacts on the engine, and it should only be done by those who have a deep understanding of the engine and its components. Improper tuning can lead to damage to the engine, decreased performance, and potential safety hazards.